Custom Tool Making of Finish Trepan Tool for the Machining Industry

Tri Star Engineering, Inc. has been committed to the manufacturing of highly specialized and complex cutting tools since 1976. Over the years, we’ve acquired the specialists and technologies required to handle every aspect of most custom tool making.

Tri Star Engineering, Inc. has been committed to the manufacturing of highly specialized and complex cutting tools since 1976. Over the years, we’ve acquired the specialists and technologies required to handle every aspect of most custom tool making.

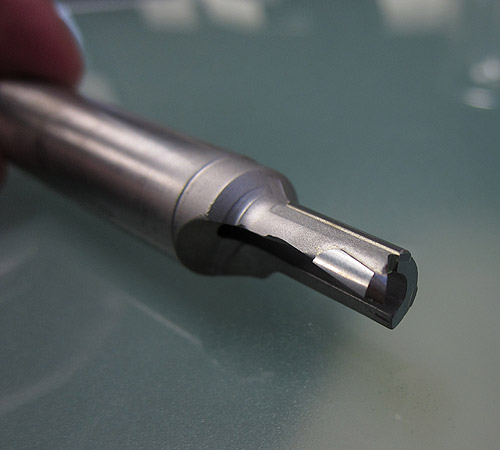

A customer asked us to produce the CAD drawings for a custom trepan tool that would be used to cut 12L14 steel. It also had to work with replaceable inserts and Tri-Star delivered. To do it, we used our tungsten carbide tips because their ability to hold their cutting edge hardness, this ensures precision and cost advantages which benefit the customer. We have a range of special coatings for all tooling.

We met the customer supplied specifications and performed the required dimension inspection.

Our expert quality team has the experience and equipment required to accurately assess the quality of our tooling’s surface finish, sizing, concentricity, and print compliance.

In today’s time-pressed business environment, we use our computerized manufacturing and tracking to monitor and control the scheduling of our products and services.

The detailed part specifications can be seen in the following chart. To learn more about our custom manufacturing, contact Tri-Star Engineering directly.