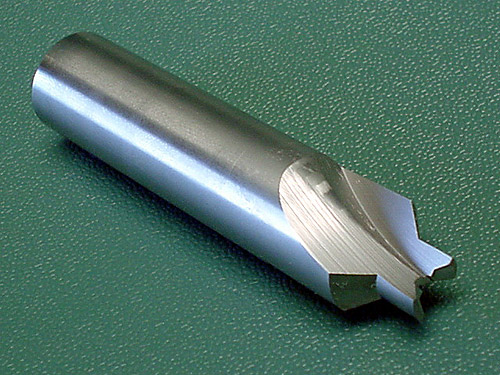

Custom Manufactured SAE J512 Inverted Flare Seat Tool for the Machining Industry

A U.S. firm located in the heart of the mid-west, Tri Star Engineering, Inc. is able to provide the expert engineering and quick turnaround time that our customers demand and expect.

A U.S. firm located in the heart of the mid-west, Tri Star Engineering, Inc. is able to provide the expert engineering and quick turnaround time that our customers demand and expect.

When a customer asked Tri-Star to manufacture a custom-cutting tool that’s used to form the components of 12L14 steel tubing, we delivered the part in carbide steel. We also have the techniques and skills required to produce an extraordinarily fine 8 RMS finish.

Our 16,000 sq. ft. facility offers six CNC grinders, which can grind both carbide and super HSS materials, a given in today’s cutting tools. Our machines allow us to provide repeatability and shorten lead times.

We constantly re-evaluate the tools we manufacture as part of our commitment to continuous improvement that targets cost, durability and turnaround. In fact, as far as we’re concerned, reducing your tooling cost per part produced is one of the most important services we provide.

You’ll find detailed specifications for this project below. We’re happy to speak with you directly to discuss your firm’s needs.